Wyffels dad’s company transforms into PPE maker, distributor

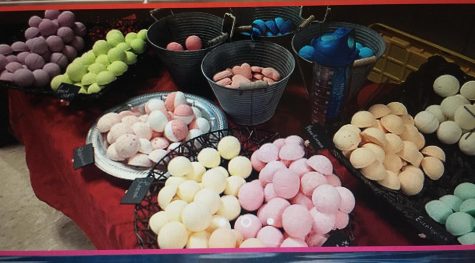

Fair use image by Charlotte Smith

Workers assemble the newly-created “open source design” face shield for surgeons across the country. Many companies such as Ford have transformed their production to making PPE as it is critically needed.

April 29, 2020

As COVID-19 rages across the country, life has changed as people knew it. Some of the most affected include business owners who have had to shut down and lose income that keep their businesses alive. Whereas others, like junior Tori Wyffels father, Chris Wyffels, have adapted to the crisis and transformed their company’s to fit the needs of the world right now.

Superior 3rd Party Logistics is a primary distribution company which coordinates where supplies and products go and how it gets there. Besides the main shipping warehouse, there is a branding warehouse where team athletic apparel is created and shipped. This segment has been changed into solely making PPE. The company is located across from the state fairgrounds in Roseville and now hosts around 20 percent more employees than before.

“These major events require businesses to look hard at how they operate and how to figure out ways to save money,” Chris Wyffels explained.

One of the company’s customers had a need for an assembly operation to support their sales so Wyffels decided to take the leap and shift the apparel warehouse to a mask-making assembly line, which makes around 20,000 face shields a day. Another customer desperately needed to get PPE into their stores for their employees which led to the company also shipping masks, gloves, eye wash kits and sanitizer to their stores.

Wyffels started the business right after the 9/11 attacks but just like this pandemic, “That did not hinder or deter the success of my business but gave me opportunities that I did not expect.”

His daughter Tori, along with some other high school students have been working there for the past few weeks, working six hour shifts and being a part of the assembly line.

These major events require businesses to look hard at how they operate and how to figure out ways to save money.

— Chris Wyffels

“I first wanted to work for my dad because I knew I could not sit idly by while the pandemic raged across the country. I wanted to help, and this was the first step,” Tori said.

She had previously worked in downtown Stillwater but lost employment due to the virus. Tori enlisted the help of some friends and fellow students at the high school to start working at the company and have a chance to get out of the house. They take precautions at the warehouse as well, wearing gloves and masks, and being at stations that are spaced apart.

Fellow employee and sophomore Ben Timmons talked about the impact having the job has had on him and feels having a job is a key to staying productive during quarantine. “I am helping out workers who help with the crisis,” Timmons added.

He likes being able to feel productive with his day, as well as make money and get to socialize with friends from a distance. Though making the shields and putting together the health packages is not a “front-line” job, it is an important aspect that often gets overlooked.

Companies like Wyffels’ are key players in combating COVID-19 and keeping people across the country employed. They bring people into work in a safe way which benefits not only the workers, but frontline healthcare workers and stores where PPE is needed.

To find out more about Superior 3rd Party Logistics and what they do, visit https://s3pl.com/